Industry knowledge

Choosing the right special customized heat shrinkable sleeve depends on various factors such as the application, the operating environment, and the specific requirements of the project. Here are some factors to consider when selecting a special customized heat shrinkable sleeve:

Operating temperature: You need to know the maximum and minimum temperature requirements of your application. This information will help you choose a heat shrinkable sleeve that can withstand the temperature extremes of your environment.

Chemical resistance: Consider the chemicals and substances that the sleeve will come into contact with. Ensure that the heat shrinkable sleeve you select is resistant to these chemicals to prevent damage and degradation.

Physical properties: Determine the size, thickness, and other physical properties that are necessary for your application. These properties will depend on the size and shape of the object you are covering.

Electrical requirements: If you are using a heat shrinkable sleeve for electrical insulation, you need to consider the voltage, current, and other electrical properties that are relevant to your application.

Environmental factors: Consider the environment in which the heat shrinkable sleeve will be used. If the application involves exposure to sunlight, water, or other environmental factors, you need to select a sleeve that can withstand these conditions.

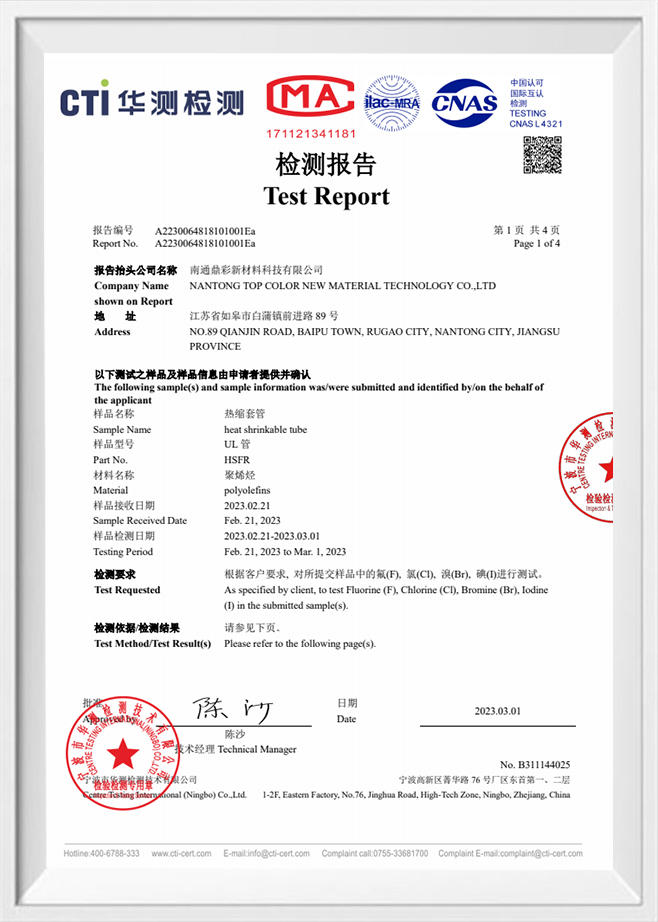

Industry standards: If you are working in a regulated industry, you need to ensure that the heat shrinkable sleeve meets the relevant industry standards.

Customization requirements: Consider any specific customization requirements, such as color coding, printing, or branding, that you need for your project.

By considering these factors, you can choose the right special customized heat shrinkable sleeve for your specific application. It may also be helpful to consult with a manufacturer or supplier of heat shrinkable sleeves to determine the best option for your project.

A transparent heat shrinkable sleeve serves as a protective cover for various types of objects, particularly cables and wires. The sleeve is made of a polymer material that can shrink when heated, allowing it to conform tightly to the shape of the object it covers. The primary function of the sleeve is to provide mechanical and environmental protection for the object it covers.

The sleeve can protect the object from abrasion, moisture, and other environmental factors that can cause damage or deterioration over time. Additionally, the sleeve can provide electrical insulation, particularly for wires and cables, which is important for preventing shorts and other electrical issues.

The transparency of the sleeve can also provide an added benefit in some cases, as it allows for easy inspection of the object it covers. This can be particularly useful in applications where regular inspections or maintenance are required.

Overall, the function of a transparent heat shrinkable sleeve is to provide a cost-effective and efficient solution for protecting and insulating a wide range of objects in various applications.

Installing a transparent heat shrinkable sleeve involves the following steps:

Choose the correct size of the sleeve based on the diameter of the object to be covered. Measure the diameter of the object and select a sleeve that has a diameter range that fits snugly around it.

Cut the sleeve to the desired length, ensuring that it is at least 20% longer than the object to be covered. This is to allow for shrinkage during the heating process.

Slide the sleeve over the object to be covered, making sure it is positioned correctly and any necessary overlaps are in place.

Use a heat gun or other heat source to apply heat evenly to the entire length of the sleeve, starting from one end and working your way to the other. Be careful not to apply too much heat in one area, as this can cause the sleeve to melt or become uneven.

As the sleeve heats up, it will begin to shrink and conform to the shape of the object underneath. Continue applying heat until the sleeve has completely shrunk and all air pockets have been eliminated.

Allow the sleeve to cool completely before handling the covered object.

By following these steps, you should be able to successfully install a transparent heat shrinkable sleeve onto your desired object.